METHOD OF OPERATION

How to operate the CD stud machine

How to operate the CD stud machine

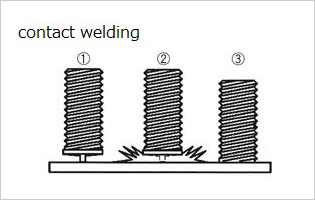

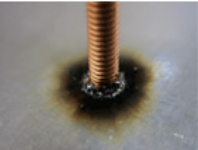

Flash stud welding (CD stud welding) instantaneously discharges and welds the electrical energy accumulated in the capacitor to the stud bolt.

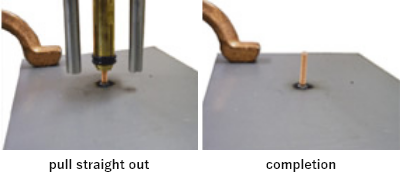

Welding can be completed siply by inserting the stud bolt into the chuck at the tip of the gun, pressing it against the base material, and pressing the switch.